Page 1 of 4

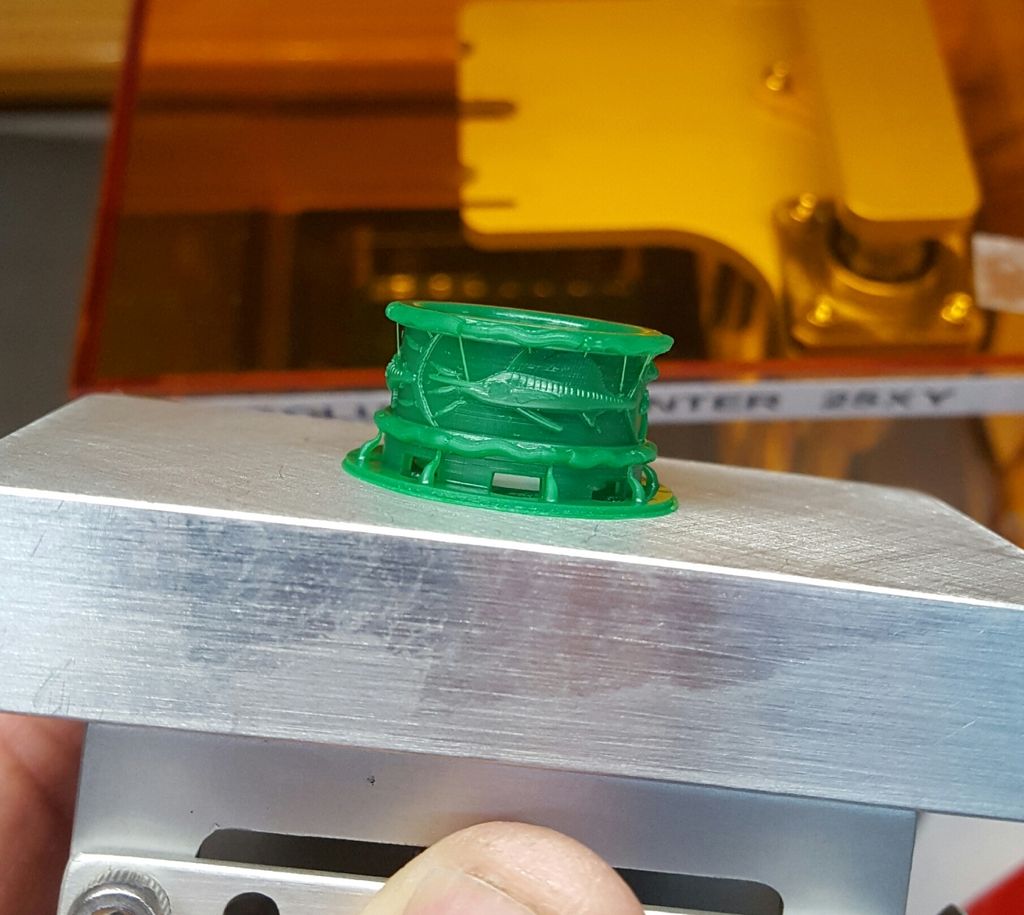

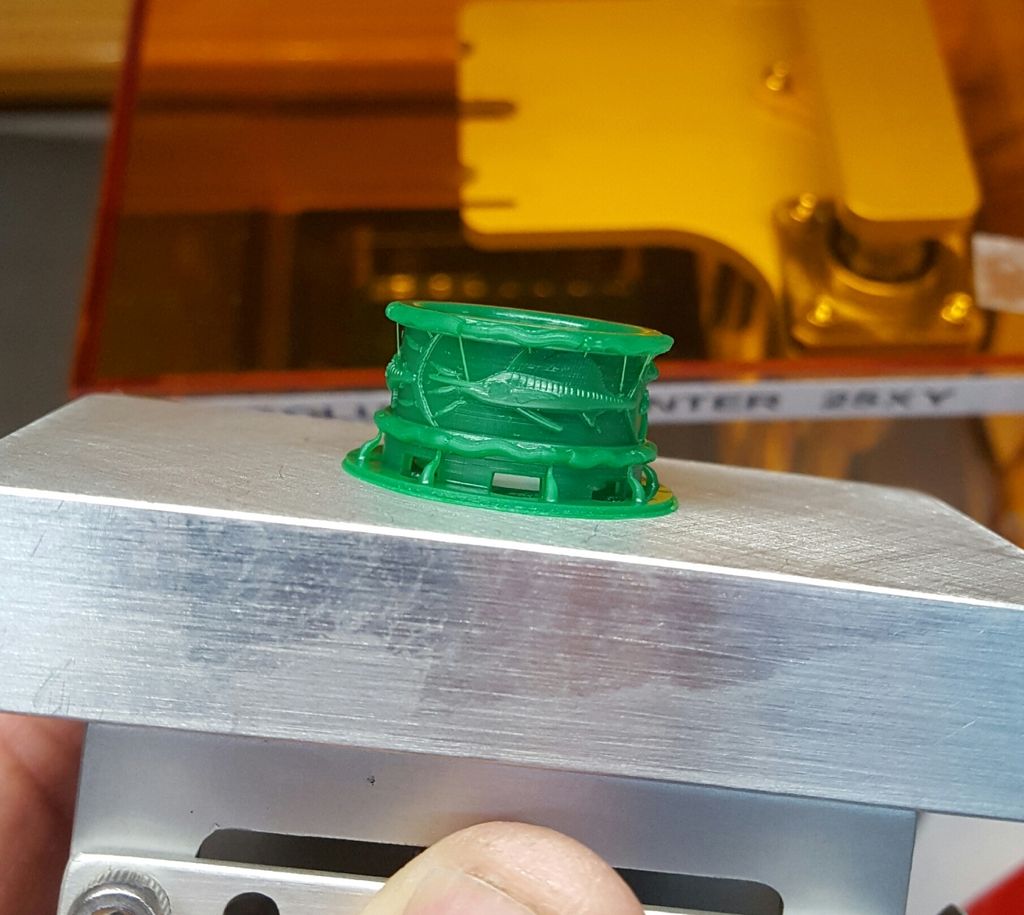

auto support on mirco prongs heavy ring

Posted: Tue May 23, 2017 4:46 pm

by dcpattni

HI,

Advice how to put less supports so i don't get mirco prongs to clean....

https://drive.google.com/file/d/0B0kqKa ... =drive_web

Re: auto support on mirco prongs heavy ring

Posted: Tue May 23, 2017 4:58 pm

by mongerdesigns

That's a tough one. I would go and manually put 0.1mm supports on those prongs that point down.

Re: auto support on mirco prongs heavy ring

Posted: Tue May 23, 2017 7:03 pm

by dcpattni

is this enough?

Re: auto support on mirco prongs heavy ring

Posted: Tue May 23, 2017 7:12 pm

by mongerdesigns

Hard to say, but I don't think so. If you support a few prongs then most likely all of them on the same row need to be supported. Use the slider on the right to see if there are any "islands" popping up created by the prong tips.

Re: auto support on mirco prongs heavy ring

Posted: Tue May 23, 2017 7:28 pm

by dcpattni

i think last i did which image above it was on ring support it grow almost nicely only 1 part at sdie top failed....

Re: auto support on mirco prongs heavy ring

Posted: Tue May 23, 2017 8:35 pm

by samatheang

I think the best way is to print it in two pieces like the pictures below, then put them back together before casting.

Re: auto support on mirco prongs heavy ring

Posted: Tue May 23, 2017 10:32 pm

by mongerdesigns

Nice suggestion, Sam.

Re: auto support on mirco prongs heavy ring

Posted: Wed May 24, 2017 1:45 am

by Jewelermdt

I was going to suggest printing it upside down. Don't think tilting would help. Would have a lot of supports on one side.

Re: auto support on mirco prongs heavy ring

Posted: Wed May 24, 2017 5:58 am

by samatheang

I tried it upside down, Mike, but still have a lot of prong pointing downward on the side of the shank.

Jewelermdt wrote:I was going to suggest printing it upside down. Don't think tilting would help. Would have a lot of supports on one side.

Re: auto support on mirco prongs heavy ring

Posted: Wed May 24, 2017 6:52 pm

by Archerm

I use very tiny micro supports to support prongs and other areas that i dont want a bunch of heavy supports. Below is a good example where you can see the micro supports very well. They are .01-.02mm in diameter.